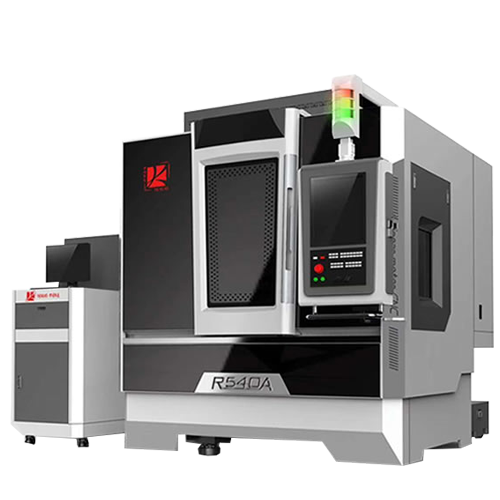

| project | R540A | |

| Machine part standard specifications | ||

| Range of work | X axis travel | 500mm |

| Y axis travel | 400mm | |

| Z axis travel | 230mm | |

| Spindle nose to table surface | 180-410mm | |

| Worktable | Table size (X-axis direction, Y-axis direction) | 500 x 400mm |

| Max. table load | 300kg (uniform load-bearing) | |

| Table shape | T slot nominal 10 x interval 100mm x 4 | |

| Spindle | Type | Built-in spindle |

| Spindle speed | 30000RPM | |

| Spindle end (nominal spindle number) | 1/10 taper HSK E40 | |

| Spindle motor | 7.5kw/11kw | |

| Maximum clamping tool diameter of spindle | 20mm | |

| Feed rate | Fast forward speed X/Y/Z | 60/60/60m/min (out machine setting is 18m/min) |

| Cutting feed rate X/Y/Z | 1-30,000mm/min | |

| Maximum acceleration X/Y/Z | 0.4g/0.6g/1.0g | |

| Tool holder magazine | Tool holder type | HSK E40 |

| Tool number of tool magazine | 20 tools | |

| Max. tool diameter | 55mm (full knife) | |

| Neighboring Knife | 115mm | |

| Max. tool length | 140mm | |

| Tool selection ways | Randomly nearby | |

| Max. tool weight | 3kg/hand | |

| Tool change time (tool to tool) | 1.55 seconds | |

| Accuracy | Positioning precision | ≤0.005mm |

| Repeating positioning precision | ≤0.003mm | |

| Required power source | Air pressure source | 6Kgf/cm² |

| power source | 3x380,8kVA | |

| Machine size | Machine siz | 2900 x 2710 x 2460mm |

| Machine weight | 4900kg | |

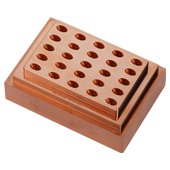

Workpiece material: copper

Machining tool: D1R0.1

Spindle speed: 19000RPM

Finishing time: 1h

Workpiece size: 50*45*14mm

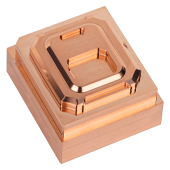

Workpiece material: copper

Machining tool: R1

Spindle speed: 18000RPM

Finishing time: 42min

Workpiece size: 47*47*16mm

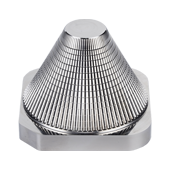

Workpiece material: copper

Machining tool: R1

Spindle speed: 18000RPM

Finishing time: 2h15min

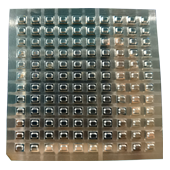

Workpiece size: 63*43*10mm

Workpiece material: S136ESR

Processing tool: PCD-R0.5

Spindle speed: 20000RPM

Finishing time: 50h

Surface roughness: Ra0.08μm

Workpiece material: S136ESR

Machining tool: R0.5

Spindle speed: 20000RPM

Finishing time: 25h

Workpiece size: 50*50mm

Workpiece material: ELMAX-HRC58°

Machining tool: CBN-D2R0.02

Spindle speed: 26000RPM

Finishing time: 12h20min

Workpiece size: 60*59mm