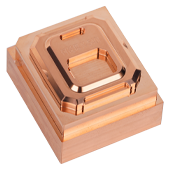

Workpiece material: red copper

Machining tool: D1R0.1

Spindle speed: 19000RPM

Finishing time: 1h

Workpiece size: 50*45*14mm

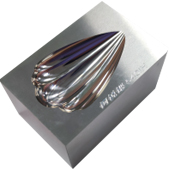

Workpiece material: S136ESR

Machining tool: R1

Spindle speed: 50000RPM

Finishing time: 20h

Workpiece size: 60*40*35mm

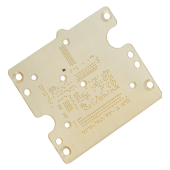

Workpiece material: PEI

Processing tool: Φ0.1mm micro hole drill

Spindle speed: 26000RPM

Finishing time: 65min

Workpiece size: 38*33*2mm

Workpiece material: aluminum 6063

Machining tool: PCD-R8

Surface roughness: Ra0.21μm

Finishing time: 3min

Workpiece size: 62*38*12mm

Workpiece material: aluminum 6063

Machining tool: R1 / R0.5

Spindle speed: 20000RPM

Finishing time: 6h15min

Processing equipment: K520i-5X

Workpiece material: graphite

Machining tool: R0.3

Spindle speed: 30000RPM

Finishing time: 4h28min

Workpiece size: 180*120*19mm

Adhere to the responsibility of manufacturing high-end CNC equipment belonging to China, and pursue the ultimate processing technology as the goal

Guanadong Precise Numerical Control Technoloav Co.. Ltd,was established inShenzhen, Guangdong Province in 2016. lt has an intelligent manufacturing equipmenbase covering an area of about 40 acres and a building area of 90000 square meters inDongguan. lt has a large temperature and humidity controlled high-precision production workshop, providing safety,stability,and intelligent production for equipmentmanufacturing.Our interpretation of PREClSE is based on the optimization of bed foun.dation structure design, reliable hardware reinforcement, secondary development ofCNC system, and pursuit of ultimate machining technology, with the aim of manufacturing high-precision CNC machine tools in China.

In addition to the production of high-precision CNC machine tools, Strontium Co..Ltd., continues to develop new andextreme processing equipment. With the concept oinnovation and development as the source of progress, it hassuccessively obtainednumber of patent certificates, the second prize of Science and lechnology of GuangdongMechanical Engineering Society, and Guangdong Provincial Machinery industnScience and Technology SecondPrize, Guangdong Province Science and TechnologyProgress Award, National High-tech Enterprise, China Machin-ery Industry Science andTechnology Second Prize,etc

The company's products are used in: high-end 3C industry, LED packacing.high-precision mold processing, opticafield, semiconductor industry, core processing ofauto parts,compressor coreimpeler processinemeoicaeduiomentorecision oartaerospace components, iquid siicone and other high-precision processing industry and.core key areas.

More