CNC machining centers

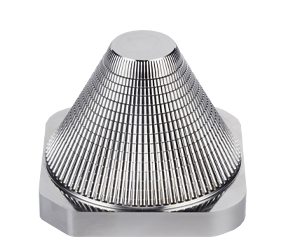

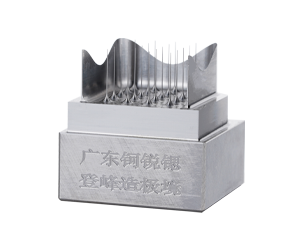

Mold production is one of the main uses of CNC machining centers. To process molds with machining centers, in order to achieve higher efficiency and precision requirements and better surface quality, it is necessary to select machine tools, tool holders, and tools. Selection, machining plan, program generation, operator requirements and other aspects are optimized.

Perfect parts are the key factor to reflect the level of mold manufacturing technology. And achieving perfection doesn’t have to be time-consuming. Strontium's high-speed machining, technology transfer, applications, software and engineering services accelerate processes while maintaining high quality and increasing productivity.

Reasonable CNC process plan: The more high-speed and high-precision machining, the more important the rationality of its CNC process plan. The whole process of processing must be effectively controlled. The design of the numerical control process plan can be considered as the control of the state of a system process plan between the parts from the blank filling to the processing and forming.

Shortened production and lead times, and reduced labor costs, are the result of rapid prototyping, high-performance milling, and electro-discharge machining (EDM) processes that do not require polishing. And that's the advantage of the Columbium Strontium technology. We match the CR-Sr equipment with CR-Sr engineering and automation services, and strive to create a single continuous operation process for mold manufacturing. This means no multiple steps and manual handling, and no need to move parts between machines. The superior finish eliminates the time-consuming step of hand polishing. In short, it's about getting flawless parts with reduced production time.

Copyright ©2021 Guangdong Precise Numerical Control Technology Co.,Ltd.All Rights Reserved Guangdong ICP No. 2021070249

Copyright ©2021 Guangdong Precise Numerical Control Technology Co.,Ltd.All Rights Reserved Guangdong ICP No. 2021070249

Service Provider:CTMON